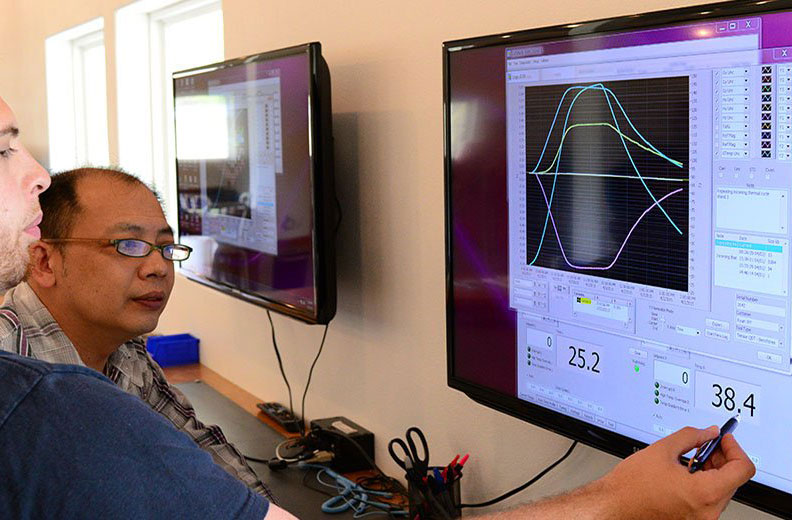

Our calibration services are the highest volume in the North American market, and utilize our own stand design along with proprietary QCalTM software. Our stand design allows for a more even and controlled temperature cycle delivering consistent and efficient calibration turns that are typically sent back to our customers in less than a week’s time. The facility uses total field calibration (TFC) rather than Helmholtz coils and has been built in the middle of our 20 acre property using Non-Ferrous materials. We use a live proton magnetometer to capture real-time changes to the field gradient and this calibrated sensor is used as an input to the calibration process to ensure that our calibrated tools will read an accurate total magnetic field (TMF) after calibrated.

Our unique calibration and verification capability can be used for almost every directional module on the market today. The process includes a full thermal calibration with our proprietary calibration routines that are then installed directly in the existing module firmware. We can calibrate at a variety of temperatures, with our own QDC product lines getting a 175°C every time.